THERMAL IMAGING

The Unseen Engine – Inside the Combustion Chamber

In issue 160 of Race Engine Technology, I wrote about the use of a Thermal Imaging System inside the combustion chamber of engines.

Whilst the article covered the fundamentals, it missed one crucial dimension: the actual video footage captured inside a running engine.

This technology is nothing short of revolutionary. It enables engineers visually track valve and piston motion, combustion dynamics, and gas behaviour in real time. Even more remarkable is that it detects temperature shifts and operating conditions with unmatched precision. For a visually driven field like engine development, this capability transforms how we understand and optimize performance.

To illustrate the power of this imaging, Professor Jon Lesko compiled four examples from a 1.6-L I4 GTDI engine that showcase the depth of insight thermal imaging can provide.

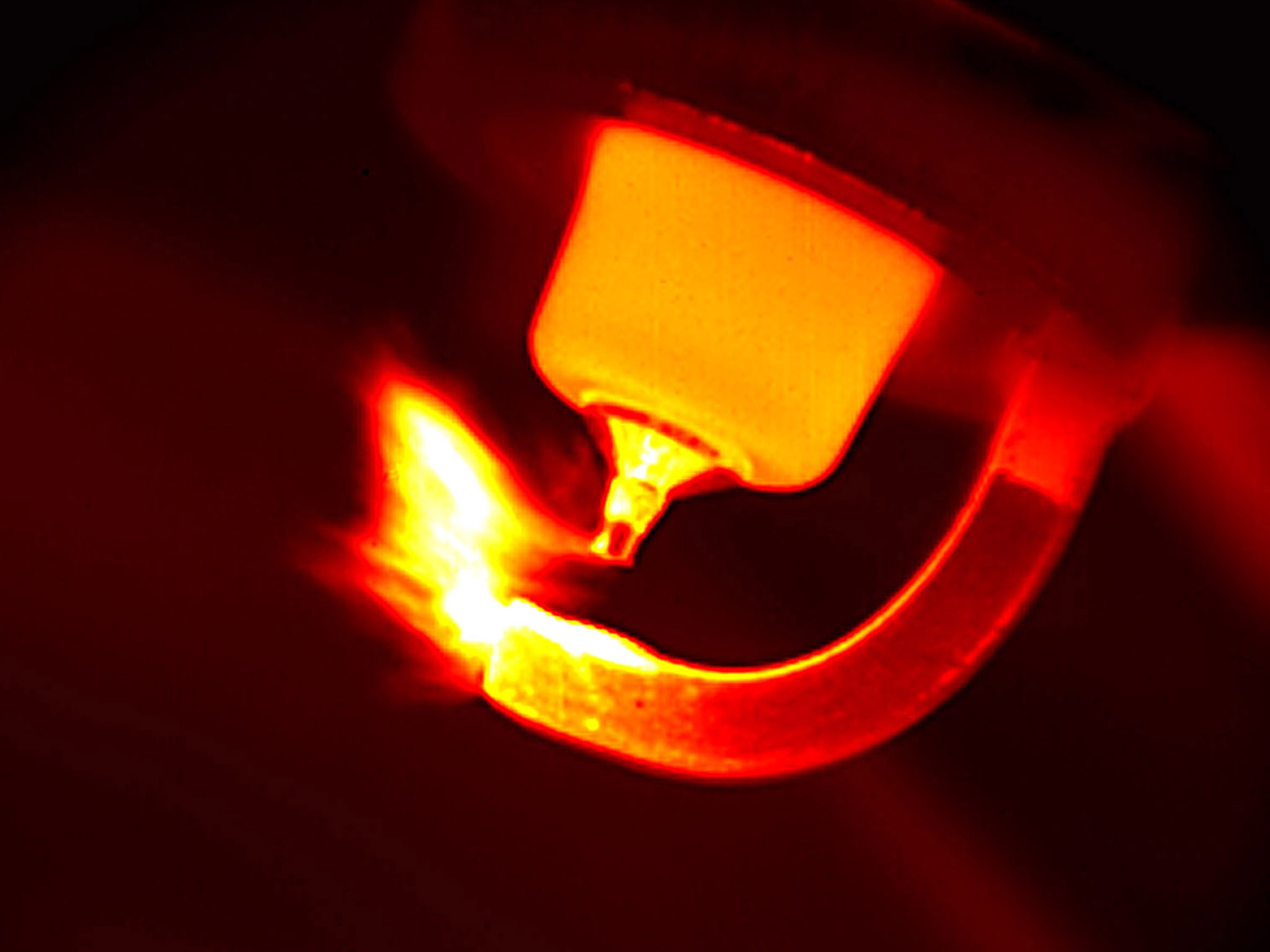

Flame Propagation and Kernel Growth

Flame kernel development is highly sensitive to the orientation of the spark plug’s ground strap. For optimal combustion performance, the strap must be positioned to minimize interference with the dominant in-cylinder charge motion; a factor especially critical in GTDI (Gasoline Turbocharged Direct Injection) engine designs. Since charge motion is shaped by the geometry and features of the combustion chamber, strap alignment must be customized for each engine configuration. This detail directly influences idle stability and throttle tip-out behaviour, where early-stage combustion plays a pivotal role in overall efficiency and emissions control.

In this particular study, cylinder one is viewed from the front, with the ground strap oriented toward the exhaust valve. The charge motion flows left to right, sweeping toward the exhaust valve. The engine operates at 2,840 RPM, 6 bar BMEP (56 lb-ft), and λ = 1—conditions that represent near-ideal combustion. Using crank-angle-resolved imaging, the video sequence captures flame kernel formation in one-degree increments up to 10° after ignition. Each crank angle is 30 samples, offering a detailed visualization of early flame growth. For comprehensive analysis, formal datasets include 300 frames per strap orientation and operating point.

These imaging datasets serve dual purposes: guiding the design of combustion systems and validating computational fluid dynamics (CFD) models. Today’s advanced simulations incorporate not only spark plug type but also ground strap orientation, which is increasingly treated as a tunable design variable in high-performance applications.

720° Rotation – Front View

At 5,000 RPM and 5 bar BMEP (47 lb-ft), a complete engine cycle of the 1.6-litre inline-four GTDI engine is captured from the front, offering a detailed thermal perspective of in-cylinder dynamics. Prominently featured in the frame is the blackbody probe, precisely positioned just left of the spark plug’s negative electrode. This probe plays a critical role in validating benchtop calibrations across multiple wavelengths, helping confirm the absorption and emission profiles of in-cylinder gases and fuels. Its temperature, influenced by combustion gases, is finely tuned by adjusting its thermal conduction path to the cylinder head. These probes are used exclusively during validation and can be inserted either manually or via automated systems.

The sequence begins with the piston moving downward and out of view, exposing the bore wall. As the intake valves open, the injector fires into the chamber, briefly obscuring both the spark plug and the blackbody probe. Injection concludes just before the intake valves reach full lift. As the cycle progresses, the intake valves rotate out of the camera’s field of view.

With the valves closed, the piston ascends toward top dead centre (TDC). Through a narrow-band 3.9 µm infrared filter, early combustion becomes faintly visible, even though many combustion byproducts remain optically transparent. As ignition intensifies, swirling gases and particulates fill the chamber, gradually dissipating as the air-fuel mixture is consumed.

The exhaust valves then begin to open, glowing brightly due to the selected integration time and display settings. At this operating point, the valves exhibit minimal rotation, a behavior not uncommon under certain load and speed conditions. As the exhaust phase concludes and the valves close, the piston completes its upward stroke, marking the end of the full 720° engine cycle.

Valve Rotation – A Design Imperative

Looking up from the top of the bore wall you can see the complete rotation of the exhaust valve after roughly 950 engine cycles. The engine is operating at 5,000 RPM and 14-bar BMEP (131 lb-ft). Over this sequence, the valve steadily heats, with rising radiance marking the temperature increase. At this condition, the exhaust valve, measured from the front of the engine, reached a peak of 851 °C at the stem-to-fillet transition. The spark plug’s negative electrode tip was even hotter, at 968 °C.

Valve rotation patterns vary by engine; some valves start from different positions or even reverse direction during operation. Designers manage these dynamics to ensure rotation occurs at speeds consistent with steady-state operation. Despite the higher speed and load, particulate output from the exhaust port did not rise significantly, showing that most particulates were consumed during combustion.

720° Rotation – Bore Wall Perspective

Captured from above the bore wall of a 1.6-L I4 GTDI engine operating at 5,000 RPM and 5 bar BMEP (47 lb-ft), this sequence offers a full-cycle thermal view from inside the combustion chamber. Prominently featured is the blackbody probe, positioned just left of the spark plug’s negative electrode. This probe serves as a calibration reference across multiple wavelengths, helping validate the absorption and emission profiles of gases and fuels. Its temperature, influenced by combustion gases, is regulated by adjusting its thermal conduction path to the cylinder head. These probes are used exclusively during validation and may be inserted manually or automatically.

The piston crown, shaped to match GTDI design principles, begins the cycle by descending out of view, exposing the bore wall. As the intake valves open, fuel injection initiates, briefly obscuring both the spark plug and the blackbody probe. Injection concludes just before the valves reach full lift, and the intake valves gradually rotate out of the camera’s field of view.

With the valves closed, the piston ascends toward top dead centre (TDC). Through a narrow-band 3.9 µm infrared filter, early combustion becomes faintly visible, despite the transparency of most combustion byproducts. As ignition intensifies, swirling gases and particulates fill the chamber, gradually dissipating as the mixture is consumed.

The exhaust valves then begin to open, glowing brightly due to the selected integration time and display settings. At this operating point, valve rotation is minimal, a behaviour occasionally observed under similar speed and load conditions. As the exhaust phase concludes and the valves close, the piston completes its upward stroke, marking the end of the full 720° engine cycle.

Future Potential: AI and Automation

Jon Lesko and his team have pioneered this imaging technology, but the next leap lies in automation. Historically, operators required extensive training to use these systems effectively. Lesko’s protocols, developed over decades, are now ripe for AI integration.

“I’ve designed a miniaturised, multi-wavelength solid-state imaging system that could be semi-autonomous,” Lesko explains. “The software I built in the late ’90s was essentially machine learning. Today’s AI can automate both acquisition and analysis, delivering near real-time data.”

This opens doors for collaboration with universities or elite motorsport teams. With accurate chamber-level data, engineers can push engines closer to their true limits—no longer constrained by the weakest link.

With proper funding, updated hardware and AI-driven software could make this a user-friendly, high-impact tool for engine development.

For further information contact:

Jon Lesko

Infrared Detection & Analysis Systems

Email: jonmlesko@gmail.com

Phone 001 (303) 808-4837

Pathompong Thongsan from Dreamstime

Pathompong Thongsan from Dreamstime

Very impressive technology. This allowed Dr. Lesko to develop a level of understanding of combustion that was previously impossible. It has opened the eyes of the industry to be able to determine just how much thermal margin they have on every item in the assembly. Very, very impressive. Thank you Dr. Lesko for sharing.

Mike