PISTON OFFSET PIN TECH

Our range of Cosworth YB pistons feature an offset gudgeon pin, which helps to reduce piston skirt wear and engine noise. To understand why, we have to consider the loads that the piston will experience.

When the piston moves up and down the bore the small end of the connecting rod will articulate forwards and backwards around the pin. This creates a loading on the piston that pushes the piston sideways. This side load varies with crank angle and is also different for each stage of the four-stroke cycle. The largest side load occurs during the power stroke, when there is a combination of inertia and gas loads that will push the piston sideways towards what is referred to as the major thrust side.

Side Loads

These side loads can have an extremely detrimental effect on the operation of the piston. For example, they can promote tilting or rocking of the piston in the bore, which in turn can increase wear at the top of the lands and at the bottom of the skirt. This type of movement can also create vibrations that are then radiated through the engine and can be heard outside the engine.

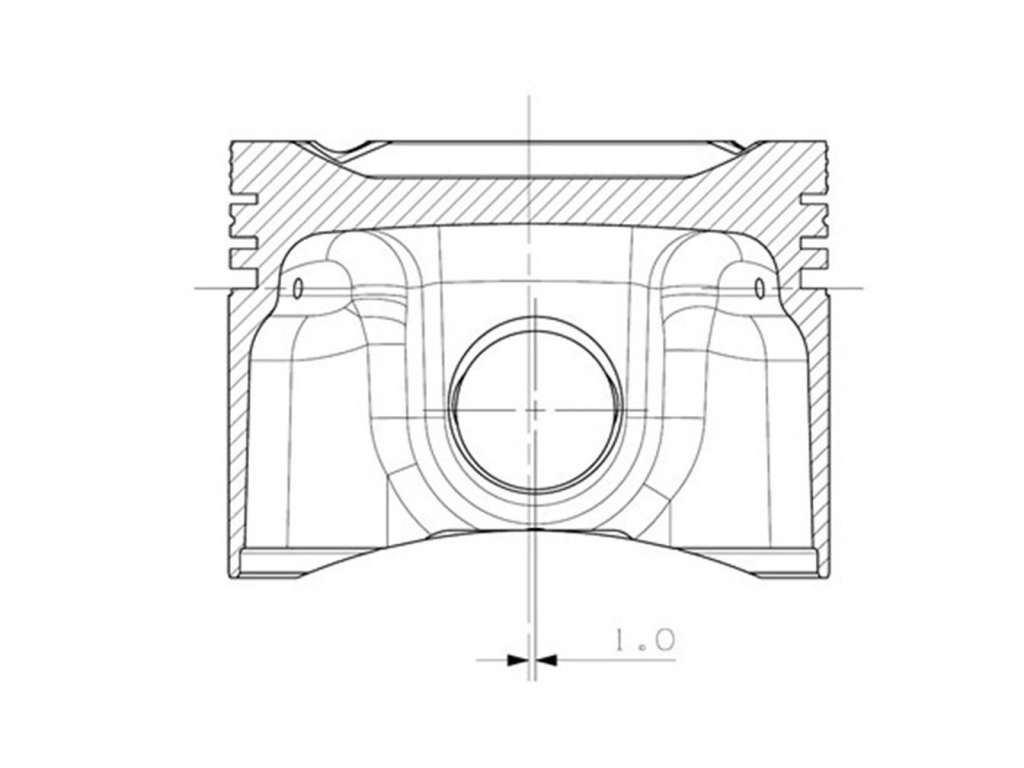

One way to reduce the major thrust side load is to offset the pin’s centre away from the cylinder bore centreline and towards the major thrust side. Even just a small offset can have a noticeable effect in reducing wear and noise during running.

If you’d like to know more about the science behind piston offset pin tech, or about the YB pistons that Cosworth makes exclusively for Modatek, then please get in touch via our Contact page.