COMING SOON – THE MODATEK CRANKSHAFT CALCULATOR!

Here is a sneak peek into something that we’ve been developing over the last few years, and we hope it will really help our customers build better engines – this is our very own crankshaft calculator, and it will be available to buy in a few weeks’ time.

To paraphrase the great Keith Duckworth & Mike Costin, I’ve spent most of my career messing about with race engines, and over the years I’ve designed numerous components, including crankshafts (writes Modatek’s Matt Grant).

In fact, Formula 1 V10 cranks were some of the first parts that I designed when I started as an engine designer in the mid-90s. The original design method to determine balancing involved reams of hand calculations and cutting out bits of paper (I kid you not!) to come up with the shapes of the counterweights.

Of course, technology has moved on a lot in the last 25 years. Today we have CAD and Microsoft Excel, and I’ve been designing crankshafts for our customers with our own software that combines CAD models and Excel spreadsheets.

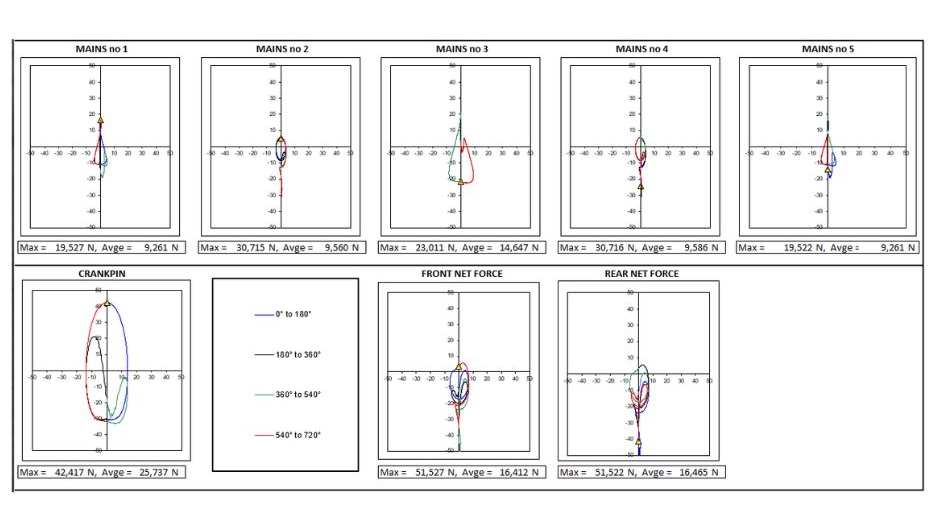

These powerful spreadsheets that not only balance the crankshaft, but also calculate bearing loads, creating plots like the one below for an I4 engine with the gas loading included:

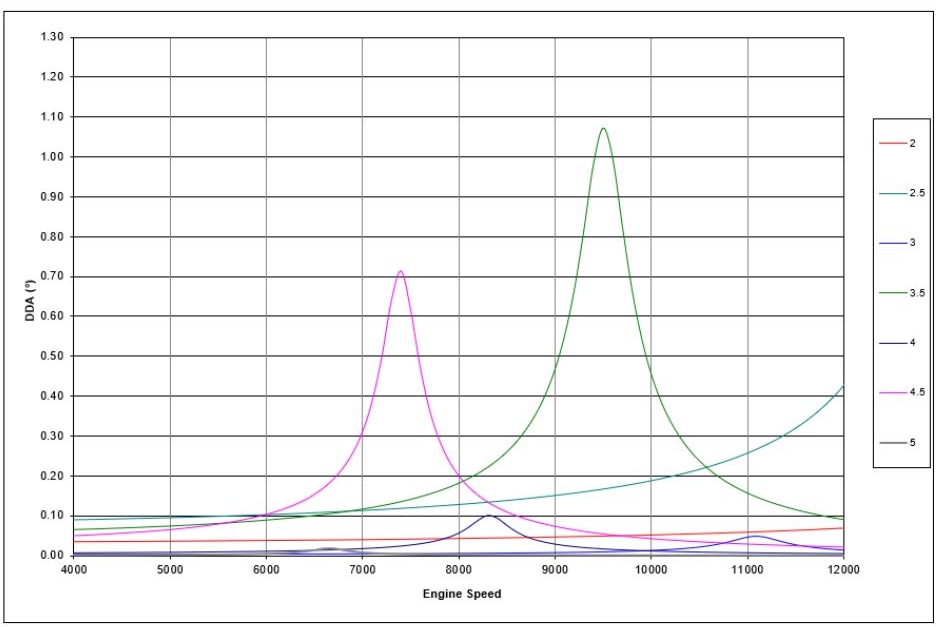

Furthermore, I’ve also created an even more complex spreadsheet that works out the first mode torsional natural frequency and the amplitudes for each order and half order. This is the predicted amplitude displacement for the I4 engine:

All of the calculations are performed in real time, there is no need for FE mesh models to be created or for complex simulations to be run.

Over the last couple of years I’ve been busy combining the balancing, bearing loads and torsional spreadsheets into one mega spreadsheet, and it’s currently being rolled out to a small number of customers. So far the feedback has been extremely positive, one customer even remarked how this is going to change the game of crank design!

So How Does It Work?

I guess that most software vendors would be very reluctant to explain exactly how their programs work, but I’ve taken the opposite view. Everything in my crankshaft calculator is based on tried and tested mathematical processes and formulae, and I’ve even written about it in Race Engine Technology.

For example, the torsional vibration calculations are based on the work done by Holzer, which in turn used equations inspired by Ker Wilson to calculate the stiffness of each section of the crankshaft.

If you want to find our more details, you can still purchase back copies of the two Race Engine Technology publications that featured these articles here:

https://www.highpowermedia.com/Product/race-engine-technology-issue-090

https://www.highpowermedia.com/Product/race-engine-technology-issue-092

If you’d like more details about the crankshaft calculator or you would like to register your interest in purchasing a copy then just get in touch via our “Contact Us” page.

Hi

I would like to have more info regarding your crankshaft design software

Thank you

Best Regards

Tomas Stenlund

UItra Motors

Hello Tomas, we’ll send you an email with all the details. Thanks, Matt