Description

How do you fancy having a Cosworth Formula 1 inlet valve on display in your home or office? Well, exclusive to Modatek, we have a small number of Formula 1 inlet valves that were fitted to the Cosworth CA2010 engines, raced between 2010 and 2013.

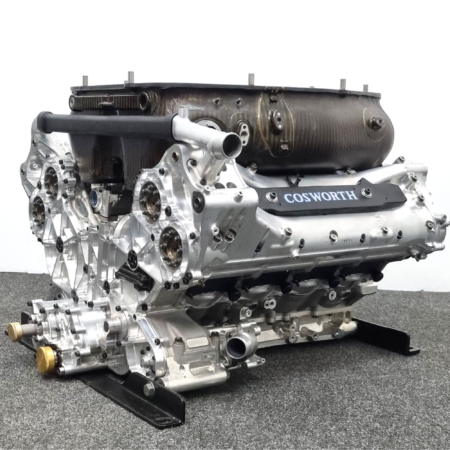

Cosworth CA Engine

The final Formula 1 engine from Cosworth, codenamed the CA, took all of the knowledge gained from decades of competition in F1 and turned this know-how into probably one of the best Cosworth engines ever. The CA was introduced in 2006 with Williams, and saw Cosworth return to the production of V8 normally aspirated engines that began with the DFV back in 1967. Capable of 20,000 rpm, the CA became the new benchmark for F1 powerplants.

After a brief sabbatical, Cosworth returned to the grid in 2010 with an updated version of the CA. By now the rules had dropped the maximum speed to 18,000 rpm. Nevertheless, the CA2010 engine was still able to produce in excess of 775 bhp. Consequently, the CA2010 was the ideal choice for both Williams and for the three new teams in F1 (Virgin Racing, Lotus Racing and Hispania Racing).

The CA2010 engine was raced for four seasons, bowing out at the end of 2013.

You can watch a short video we put together of a Cosworth CA2010 engine being pushed through its paces on Cosworth’s transient dyno at speeds of up to 18,000 rpm – just click here.

Cosworth Formula 1 Inlet Valve

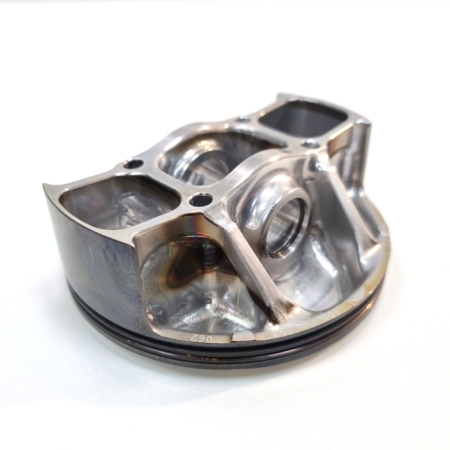

The inlet valve in a Formula 1 engine has to survive extreme temperatures and loads, and at speeds of 18,000 rpm the inlet valve is moving up and down 150 times per second. The only way to make the valve survive long enough is to make it as light as possible. Hence the Cosworth CA2010 inlet valve has a stem diameter of just 5 mm, which tapers down to less than 4.5 mm nearer the head.

The Cosworth CA2010 inlet valve also has a very clever design feature to increase performance. Just ahead of the seat face is a raised lip that is intended to disrupt the gas flow coming into the combustion chamber, resulting in turbulence. The turbulence created has been found to assist the flow of the gas around the corner of the valve head and across the face of the valve, which is particularly beneficial on a valve with a flat face.

Please note that these valves have been run and hence have carbon deposits on the head and blend radius to the stem.

Details:

- Length= 109.4 mm

- Head diameter = 41.3 mm

- Weight = 30 g

- Material = High strength titanium alloy