Did you watch the latest season of Drive to Survive on Netflix and wish that they had made something similar for previous decades of Formula 1 racing? Well, we did, so we went off hunting through the murky corners of the internet, and here are the top five retro videos that we found. Naturally, they are linked to Cosworth, some more tenuously then others. Just click on the images to see the videos. Please note that we are not responsible for any external links.

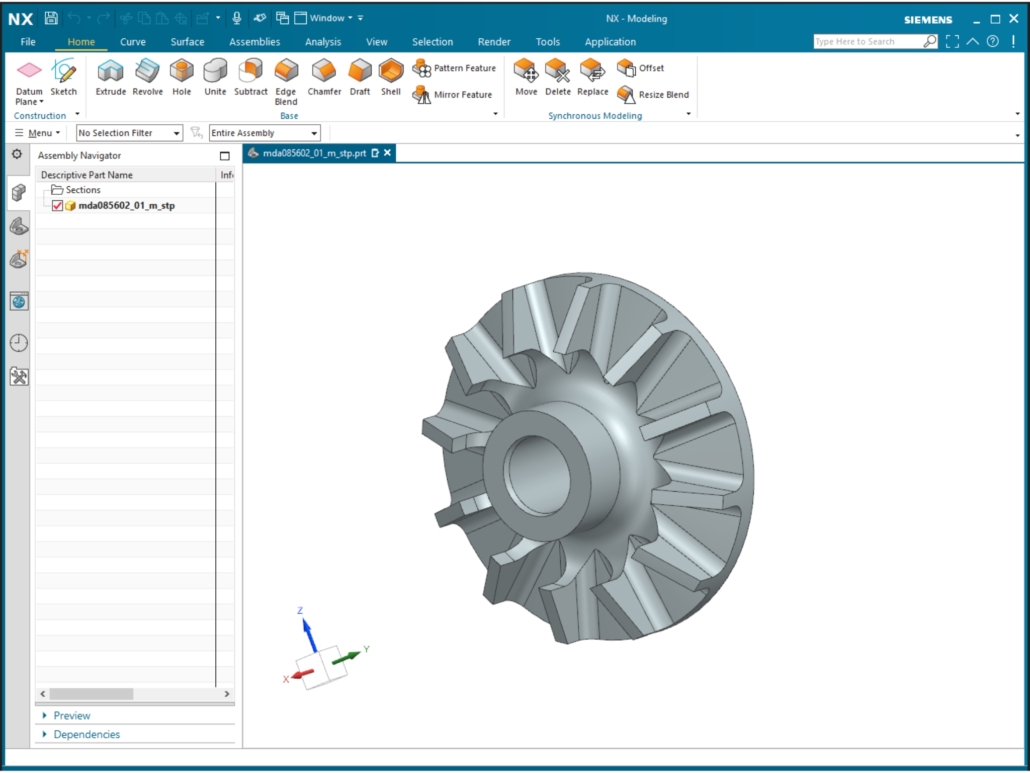

#1 : 1986 Cosworth GBA Engine (Equinox)

In the mid-80s Cosworth were faced with the growing reality that the DFV had been usurped by the car manufacturers with their immensely powerful turbo engines. Finally, Cosworth were given the green light by Ford to create their own turbo engine, the GBA.

This video provides a fascinating insight into the design and manufacture of the GBA, from the initial forays into trying to run a turbocharged BD engine right through to the first track tests of the GBA in the Beatrice Lola.

Favourite quote: “The dents on the temporary sump seem to suggest some sort of internal explosion” – that’s a slight understatement!

#2 : 1967 Cosworth DFV (Nine Days in Summer)

Despite the slightly tedious background music, this is an entertaining video that takes a look at the birth of the Cosworth DFV engine alongside that of the Lotus 49. The video below is an extract from the full film, which you can still buy today from Duke Video.

Favourite quote: “It’s got some poke, not a bad old tool” is Graham Hill’s initial assessment of the DFV after his first test drive.

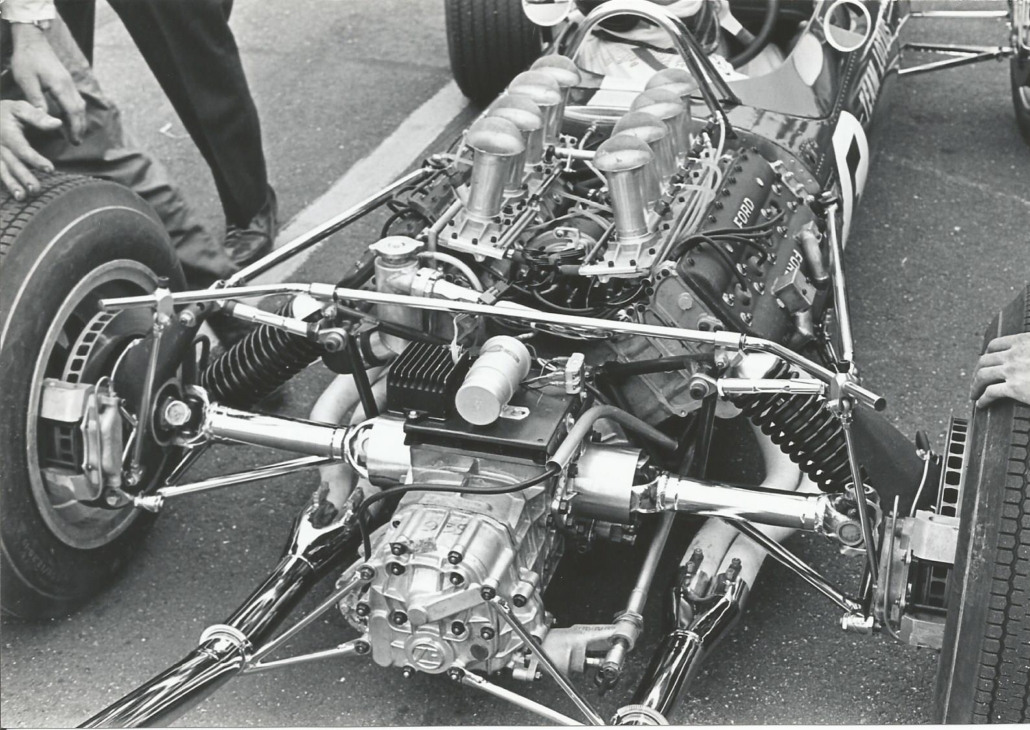

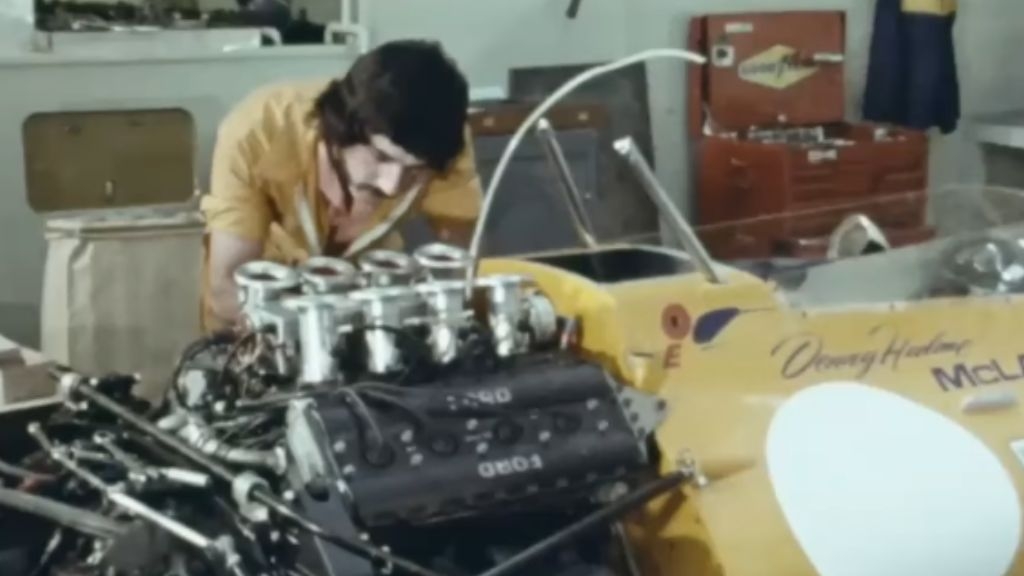

#3 : 1971 McLaren M19

Another DFV-related video, this short clip looks at the building of the McLaren M19 that raced in 1971. The car looks incredibly low tech by today’s standards, but back then the M19 was a race winner.

Favourite quote: “This car looks very sort of primitive and generally very uncomfortable” – not the sort of thing you should say in the middle of a car build shop!

#4 : 1993 McLaren MP4/8 (The Team – A Season with McLaren)

In 1993 McLaren gave a film company unprecedented access to what went on behind the scenes, creating a number of episodes that looked at a range of topics, including the often-thorny relationship between Ayrton Senna and Ron Dennis. Just imagine how ‘Drive to Survive’ would have portrayed this!

The MP4/8 was powered by the Cosworth HB engine at the 11th hour following Honda’s withdrawal, and it comes under some fairly unfair criticism (in my opinion, anyway!).

Favourite quote: “Ayton is positive there is something wrong with his engine, but the engineers are not so sure.” In an era before huge reams of data from telemetry, they had to trust Senna’s judgement, and he proved to be right.

#5 : 2003 Jordan EJ13

OK, this isn’t strictly a ‘Drive to Survive’ style look at the team, but it does show what went on in the crazy world of Eddie Jordan. The film follows Jordan around for a day, which just happened to be the same day that the new EJ13 car was shaken down. I’m slightly biased here because I was at the test, and I’m convinced that I can see my head in the background.

The EJ13 used the Cosworth LK engine, which was a development of the CK engine that first ran in 1999 with the Stewart Grand Prix team. Although the team fared fairly badly in the 2003 season, they did at least win a race.

(By the way, the title on the video is wrong, it was definitely 2003 because I was there!)

Favourite quote: “I normally come out with bruised ankles, he always makes sure that he sits next to me and I get kicked” – commercial director Ian Phillips reveals what its like going into negotiation meetings with Eddie Jordan.

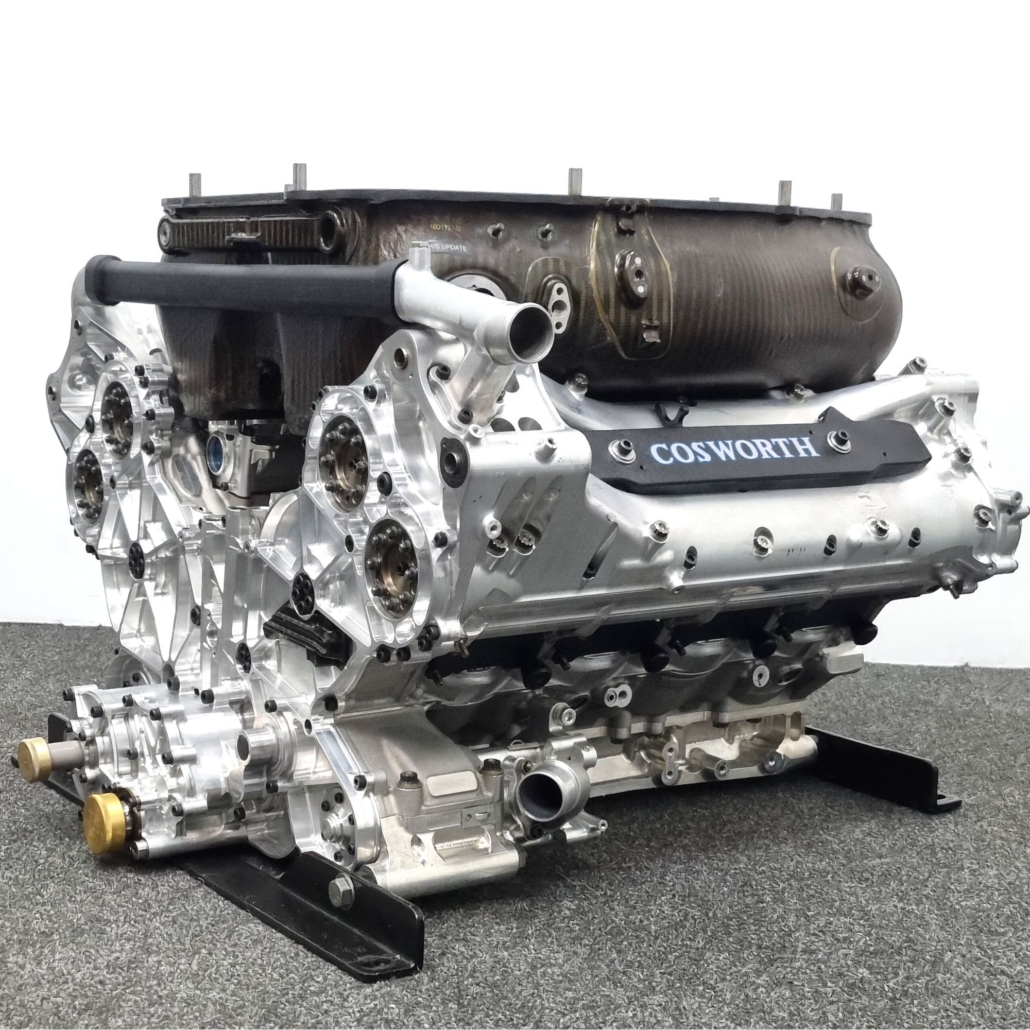

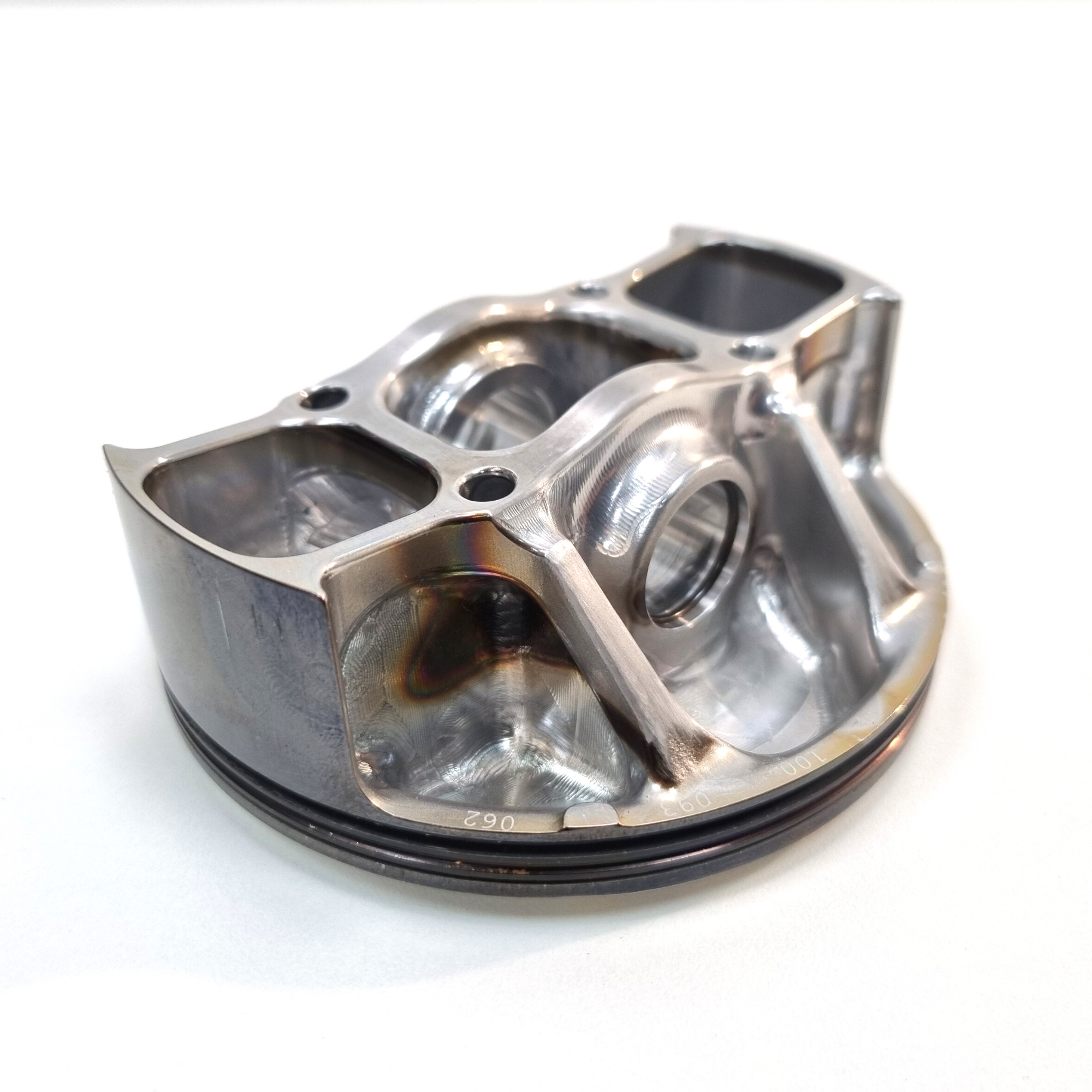

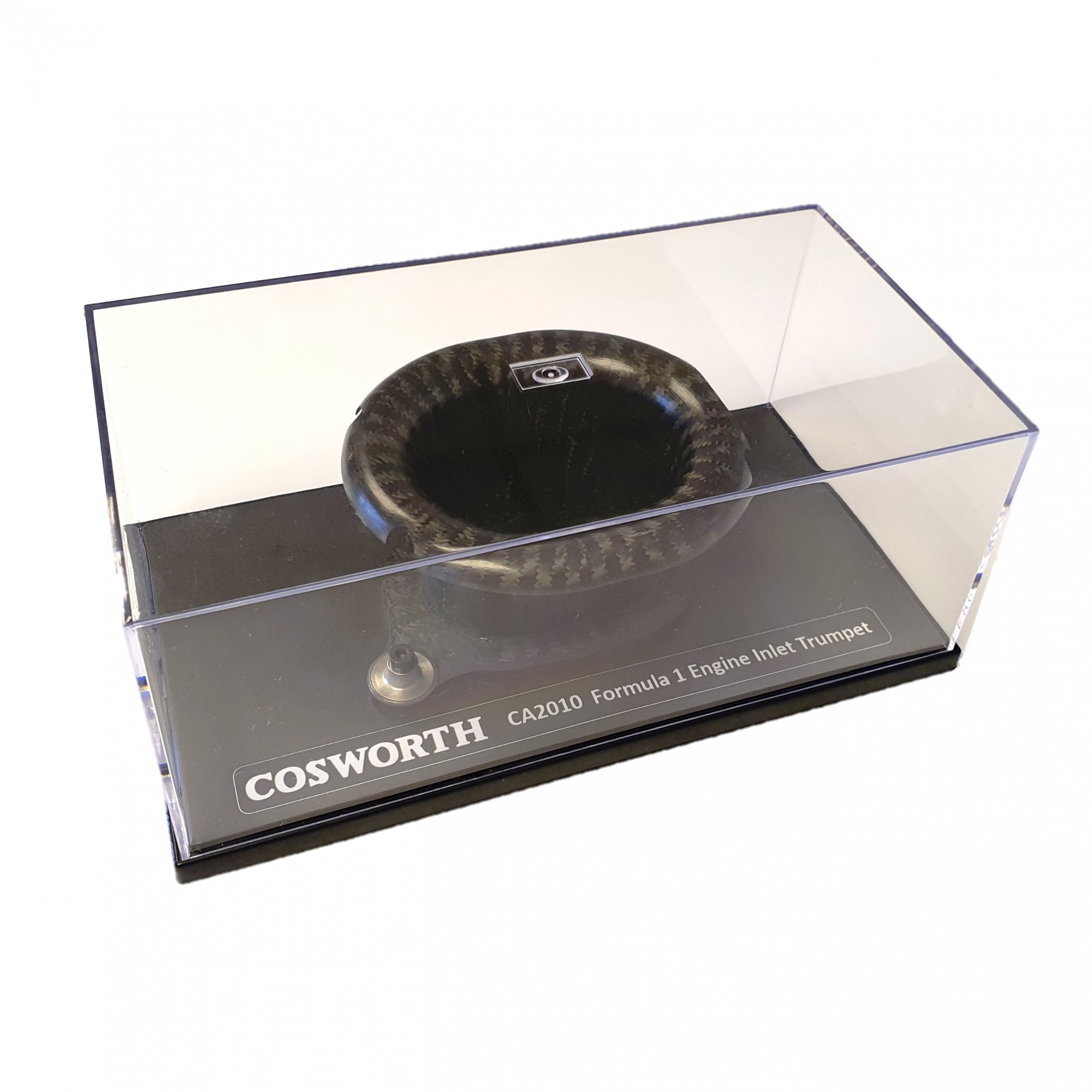

We are Cosworth’s official distributor for their historic engine parts, and we supply a wide range of parts for a number of different Cosworth historic engines, from BD, YB and DFV through to the more recent F1 engines like the CK, TJ and CA. Our mission is to help our customers build better engines by supplying high quality parts backed up with a design consultancy that utilises over 25 years experience in top level motorsport.